The Ultimate Guide to Belt Pulley Alignment: Everything You Need to Know

Everything You Need to Know

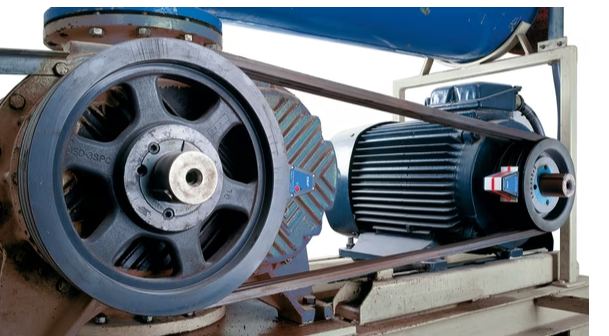

In the field of machinery, belt pulley alignment is an important but sometimes disregarded factor. It serves as the backbone, maintaining synchronisation between different parts to guarantee peak performance. Gaining proficiency in the finer points of such alignment is similar to being a master precision engineer. We go further into the subtleties of belt and pulley alignment in this extensive article, demystifying its intricacies and providing useful advice for both amateurs and experts.

Belt Pulley Alignment: What Is It?

The fundamental idea behind belt pulley alignment focuses on accurately positioning pulleys within a system. This procedure entails aligning the pulley grooves to guarantee smooth belt movement without slippage or excessive strain on the equipment. Picture it as arranging pulleys like a symphony, each contributing to the harmonious operation of the system.

The Significance of Accurate Alignment

- Reduces Down Wear and Tear: Accurate pully and belt alignment can reduce the premature wear and tear increasing the lifespan.

- Boosts Efficiency: A system that is aligned runs more smoothly, using less energy and being more efficient overall.

- Reduces Vibration: Vibration is often a by-product of misalignment. By ensuring the pulleys are properly aligned, vibration within the machinery is drastically reduced, which can also decrease noise levels.

- Avoids Unexpected Downtime: Misalignment might result in expensive downtime due to unanticipated equipment problems. These problems may be avoided with routine inspections and alignments.

- Enhances Safety: The possibility of accidents resulting from increased vibration or component failure is decreased by proper alignment.

Techniques for Alignment

To get exact alignment, a variety of methods are used, each designed to meet particular needs and purposes. With improved precision and efficiency, the array of alignment technologies keeps growing, ranging from laser alignment systems to straight-edge techniques. But developing these skills takes time, repetition, and an acute sense of detail.

Typical Alignment Problems

Alignment technology has advanced, yet basic problems still plague even the most well maintained systems. Sheave runout, eccentricity, and belt slippage are a few of the worst offenders that seriously impair equipment operation. It is critical to quickly identify and resolve these problems in order to stop more harm and disruption.

Best Practices for Alignment

Adherence to best practices developed through years of industry expertise is necessary to navigate the complexities of belt pulley alignment. Proactive troubleshooting and frequent inspections and maintenance are the cornerstones of successful alignment management. Furthermore, spending money on high-quality parts and alignment tools may pay off in the long run by reducing the need for expensive maintenance and replacements.

The Component of Humans

In the thick of the precise engineering and technical speak, it’s important to remember that alignment projects always include people. Expert technicians and engineers are essential to maintaining alignment precision because they use their knowledge and instincts to adjust machines to the ideal level. The foundation of effective alignment procedures is their commitment and meticulousness.

Factors Influencing Alignment

Belt pulley alignment may be greatly impacted by a number of variables, which can affect equipment lifetime and performance. Recognising these elements may assist in identifying problems with alignment and putting workable fixes in place. Here are some important factors to think about:

- Thermal Contraction and Expansion: Variations in temperature may cause materials to expand or contract, which can affect how pulleys align. To maintain alignment, variations in ambient and operating temperatures must be closely observed and adjusted as needed.

- Stability of the Foundation and Support Structure: Alignment depends on the base and support structure of the machine being stable. Any movements or settlements may cause misalignment, requiring regular inspections and calibrations.

- Wear & Tear by Mechanism: Belts, pulleys, and bearings all experience wear and tear over time, which changes their dimensions and alignment issues. To see wear early and take appropriate action, routine maintenance and inspection are crucial.

- Poor Maintenance or Installation: Misalignment may occur suddenly or gradually as a result of improper pulley and belt installation or inadequate maintenance procedures. These dangers may be reduced by making sure installation follows product specifications and by performing regular maintenance inspections.

- External Forces and Vibrations: Alignment may be disturbed by external forces, such as vibrations from nearby equipment or outside influences. Maintaining alignment may be facilitated by putting vibration damping measures in place and making sure there is enough space between equipment.

Upcoming Developments in Alignment Technology

With the continuous advancement of technology, belt pulley alignment is a constantly changing field. Real-time monitoring tools and predictive maintenance algorithms are two emerging innovations that have the potential to completely change alignment management. Stakeholders may usher in a new age of efficiency and dependability by proactively identifying possible alignment problems before they worsen by using data analytics and artificial intelligence.

In summary

To sum up, learning the craft of belt pulley alignment is a difficult and intricate path. But with the correct information, persistence, and equipment, even pros and amateurs can confidently traverse this terrain. We can unleash the full potential of machines and bring in an age of unmatched efficiency and dependability by comprehending the subtleties of alignment, abiding by best practices, and valuing human interaction. So let’s go off on this adventure together, towards a day when belt pulley alignment is a monument to human creativity and accuracy is paramount.